The Technology

Pressure leaf filters utilize the concept of cake filtration to deliver an economic and reliable solution for liquids with higher solid loads, between 0.01% – 3%. The system is comprised of a pressure vessel containing individual ‘filter leaves’ supported on a manifold.

During operation, the fluid flows into the pressure vessel where it is pushed through the filter leaves. Filtered fluid exits the vessel via the manifold. Captured solids on the filter leaves build a filter cake which ultimately needs to be removed. This can be accomplished either by draining the housing, drying the cake and ejecting with a pneumatic vibrator, or alternatively the cake can be sluiced and discharged.

Selecting the right pressure leaf filter technology for your application will depend on many factors like the flow rate, continuous or batch processing, the type and amount of solid load, nature of the liquid, temperature, and the fluid viscosity.

Our Product

Utilizing best in class technologies, we design and engineer Envi Leaf pressure leaf filters to optimize cake discharge properties. The Envi Leaf long-lasting filter elements are designed for low maintenance and infrequent changeouts, which combine to deliver highly efficient filtration with lower operating costs.

Advantages of Envirogen Envi Leaf pressure leaf filters:

- High flow rates in a compact design – Envi Leaf pressure leaf filters operate at high flow rates and at pressures of up to four bars.

- Robust filter leaves and filter mesh – Expect long life from the robust five layer stainless-steel wire mesh, delivering a low total cost of ownership with little maintenance.

- High-efficiency – High filtration efficiencies are delivered, with or without use of a filter aid.

- Flexible design – The filtration area of Envi Leaf pressure leaf filters is sized for your application. Our vertical vessels are offered in filtration areas from 5m² to 125m².

- Multiple uses – Multiple filtration stages can be accomplished by changing out the filter leaves for coarser or finer mesh.

- Quick cake discharge – Our fast drying process minimizes liquid loss during cleaning cycles, while our air vibration system discharges the cake, quickly and easily.

- Durable design – To prevent damage during cleaning, our unique u-shaped nozzle is enclosed within a manifold, creating a strong attachment with the tank, and allowing smooth flow. In addition, Envirogen leaf handles are welded to the outside of the U-profile to prevent leakage if the handle is damaged.

- Designed for safety – The closed filter system ensures safe operating conditions even at high temperature and pressure.

Envi Leaf systems are available in both horizontal and vertical styles that can be used with both wet and dry cake discharge. Our pressure leaf filters are offered with a variety of filter meshes to meet the needs of a range of fluid applications including edible oils, gelatin, liquid sulfur, and bio-diesel. The 316L or 904L materials of construction used in our PZ80, 60 mesh, and 24×110 Dutch weave filter leaves, assure they can withstand the rigors of these demanding applications.

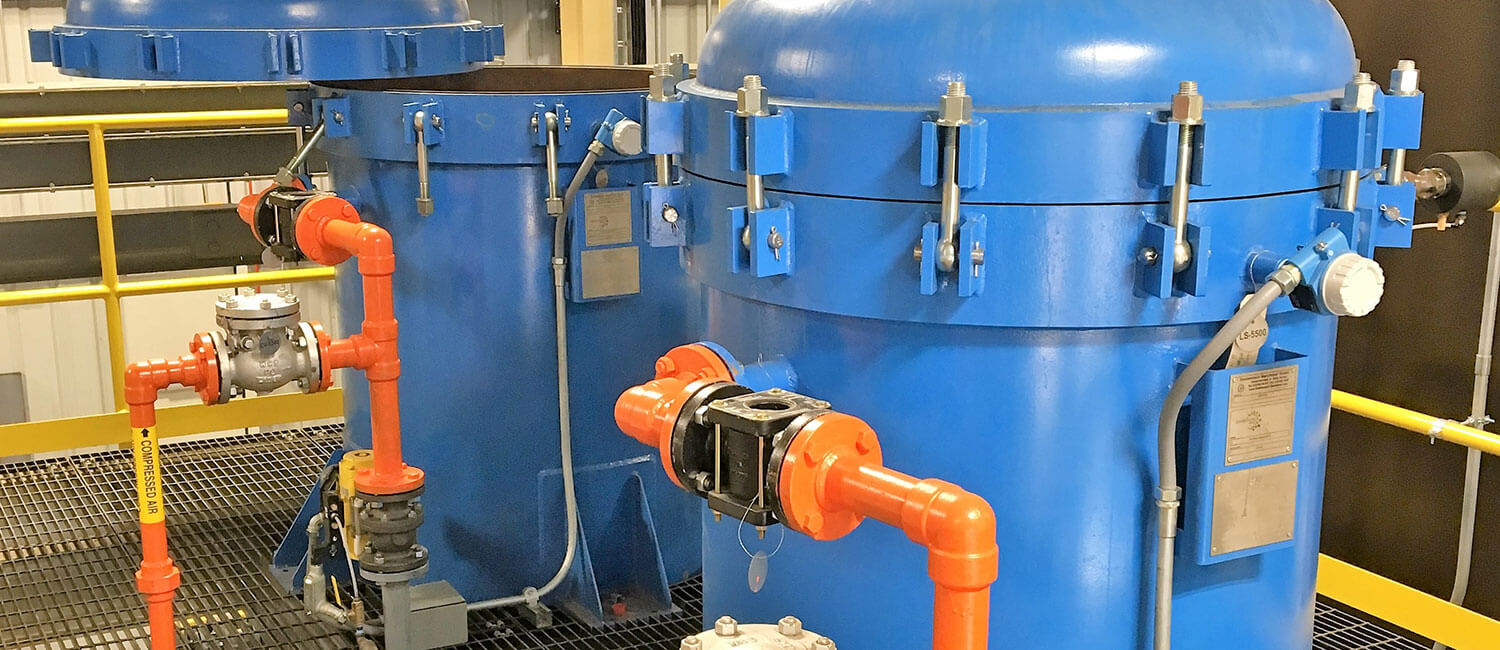

Vertical pressure leaf filter

In a vertical pressure leaf filter, the rectangular filter leaves are mounted vertically in a vertical oriented tank, and are connected to a filter manifold at the bottom of the tank. When the filtration process is completed, the dry filter cake is discharged by use of a vibrator.

Horizontal pressure leaf filter

The filter leaves in a horizontal pressure leaf filter are also mounted vertically, but the filter tank is horizontal. Compared to vertical pressure leaf filters, the horizontal filters can have a large filtration area. This orientation also allows for visual inspection of the leaves to assure full cake discharge after use. For dry cake discharge, many customers opt for the addition of a vibrator.

Applications

Typical markets and applications for pressure leaf filters include:

- Edible oil processing (crude oil, bleached oil, winterized oil)

- Gelatin processing

- Pectin processing

- Glucose, sweeteners, sugar, fruit juice production

- Biodiesel production (pre-treatment and polishing)

- Liquid sulfur filtration

- Chemicals and oleochemicals

- Organic and inorganic salts, amines, resins, and bulk drugs

Filter Leaves and Spare Parts

Pressure leaf filters are installed in thousands of installations worldwide. While the filter vessels operate for decades, the filter leaves need to be replaced a few times during the lifetime of the vessel.

The quality and condition of your filter leaves are critical to the productivity and performance of your pressure leaf filter system. Replacing worn or damaged filter leaves will result in an immediate improvement in system performance.

Envirogen offers high-quality filter leaves for almost every make or model of pressure leaf filter available on the market. Our Envi Leaf filters have a reinforced box profile as standard with a five-layer mesh configuration and the very latest in high-flow nozzle technology.

Our high-quality Envi Leaf filter leaves and filter plates are available in a variety of materials, with a range of structures to suit every filtration task:

60 Mesh

- Plain weave filter screen

- Wire diameter: 0.19mm, 240µm

- Available materials: 316L, 317L, 904L stainless steel

24 x 110 Dutch weave

- Plain weave filter screen

- Wire shute diameter warp: 0.35mm, 0.25mm, 125µm

- Available materials: 316L, 317L, 904L stainless steel

PZ80 (reversed plain Dutch weave)

- Dutch weave filter screen

- Wire shute diameter warp: 0.35mm, 0.25mm, 90µm

- Available materials: 316L, 317L, 904L stainless steel

Envi Leaf filter leaves provide:

- Longevity – with five layers (plies) of stainless-steel wire mesh, each internal filter leaf is robust and designed for long-life

- Reduced maintenance – delivering a low total cost of ownership

- Years of service –long service life for each leaf

- High-efficiency – with excellent pre-coating properties

- Flexibility – Envi Leaf filter leaves can be customized for any filter vessel and can be used in multiple steps in the filtration process.